Made in India Semiconductor Chips by End of 2025

Made in India Semiconductor Chips by End of 2025

On August 15, 2025

India’s first domestically produced semiconductor chips will reach the market by the end of 2025—a milestone in the country’s push for tech self-reliance. Multiple reports from national outlets echoed the timeline and highlighted that the government is driving semiconductor projects in mission mode.

Editor’s note: This article is intended for general information. For specifics like node sizes, volumes, and product categories, watch for official commissioning updates from the companies and ministries involved.

![]()

What Is a Semiconductor Chip?

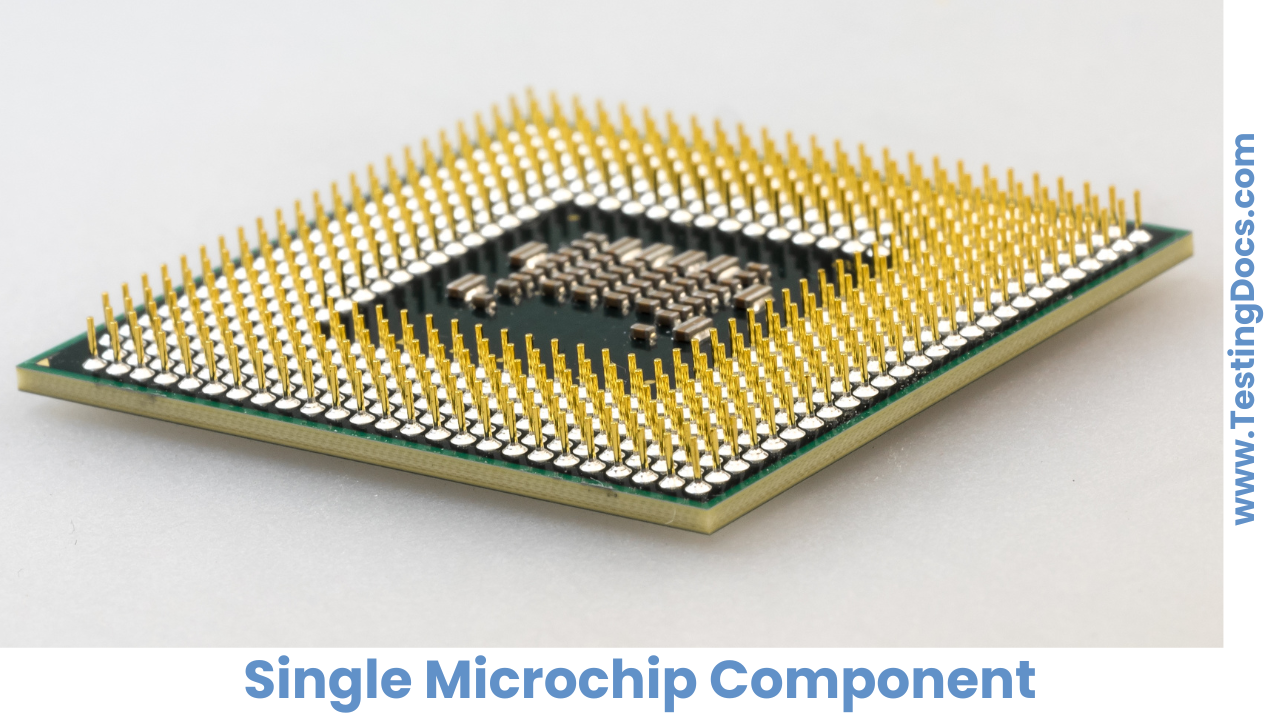

A semiconductor chip (often just called a “chip” or “microchip”) is a tiny slice of material—usually silicon—etched with millions to billions of electronic components that process, store, or move information. Different chip types do different jobs: Processors (CPUs), Memory (DRAM, NAND), Microcontrollers, Sensors, Power management, etc.

Uses of Semiconductor Chips

Some of the uses of Semiconductor chips are as follows:

- Phones & Laptops: Power the CPU, graphics, memory, storage, and connectivity.

- Automobiles: Control braking, engine timing, battery management, infotainment, and driver-assist features.

- Industrial & Energy: Run factory automation, robotics, smart grids, and renewable energy inverters.

- Consumer Electronics: TVs, wearables, gaming consoles, cameras, smart home devices.

- Networking & Cloud: Data centers, 5G equipment, routers, and switches.

- Defense & Space: Navigation, communications, radar, and mission-critical control systems.

2025 Timeline

Government statements indicate an accelerated push: approvals for new units, ongoing build-outs of fabs and OSAT/ATMP facilities, and targets aligned to get first domestic chips into the market by 2025-end. Reports also note major projects (including assembly & test) entering critical cleanroom validation and gearing up for partial operations in H2 2025.

Top FAQs

Is the 2025 date official?

Yes—India’s Prime Minister publicly stated that “Made in India” chips will hit the market by the end of 2025, a timeline reiterated across major outlets.

What kinds of chips are likely first?

Early production typically focuses on mature-node logic, power, and packaging/assembly categories before moving to more advanced nodes. Government and media coverage suggest a ramp that includes fab work alongside ATMP/OSAT capacity to get marketable products out in 2025.

Will this make gadgets cheaper in India?

Not immediately. Prices depend on many factors (global demand, input costs, yields). However, local capacity can improve supply resilience and, over time, help reduce logistics and import costs—benefits that can trickle down to consumers.

What’s the difference between a fab and an ATMP/OSAT plant?

A fab creates the silicon wafers and etches circuits (the “chipmaking”). ATMP/OSAT plants assemble, package, and test chips after they come off the wafers. Both are essential for getting finished chips into products.

How confident should we be about the timeline?

Large semiconductor projects are complex and can face delays. Still, the Independence Day commitment and visible progress at facilities entering validation in 2025 point to a realistic chance of initial “Made in India” chips by year-end.

Which projects are in motion right now?

Media and company updates highlight multiple units across Gujarat and other states, including assembly & test projects advancing towards 2025 operations, with gradual capacity ramps thereafter.