PDCA Cycle

PDCA Cycle

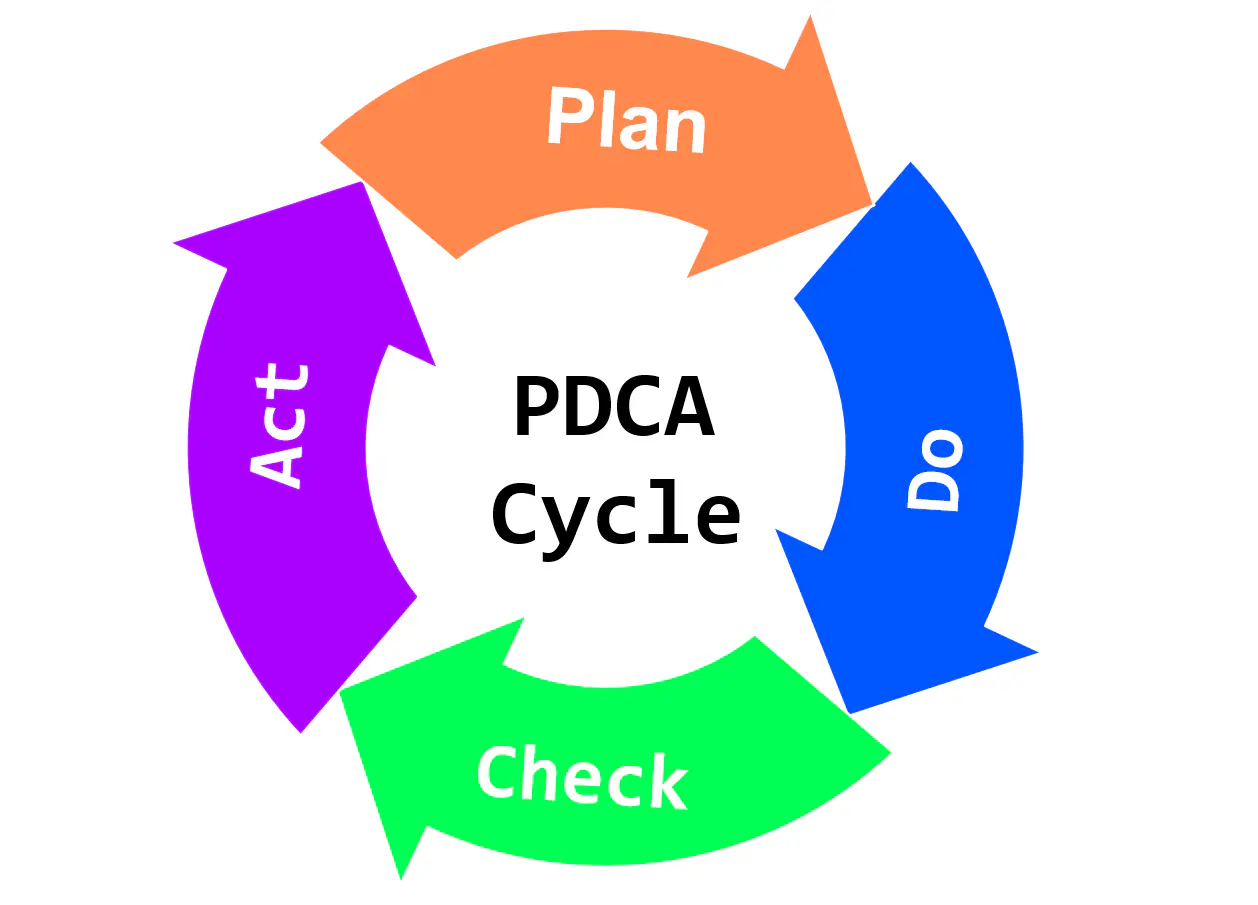

The PDCA Cycle, also known as the Deming Cycle or Plan-Do-Check-Act, is a four-step model used for continuous improvement in business processes, quality control, and project management. It’s widely used in various industries to drive systematic and iterative improvement.

The PDCA cycle is also known as The Deming Wheel. It is a model for continuous improvement in quality management developed by Dr. W. Edwards Deming. It is a systematic series of steps for gaining valuable knowledge and improving a product or process continuously.

What is PDCA?

The PDCA cycle is a loop of four stages that help teams and organizations solve problems and implement change effectively. The PDCA cycle has four steps as follows:

- Plan

- Do

- Check

- Act

Plan

Identify a goal or purpose, formulate a theory, define success metrics, and implement a plan.

-

Identify a problem or opportunity for improvement.

-

Set goals, define the desired outcome.

-

Analyze the current situation and identify root causes.

-

Develop a plan with specific steps and resources.

Example: A software company identifies that customer support tickets are taking too long to resolve. They plan to introduce a new ticket prioritization system.

Do

Implement the plan on a small scale.

-

Implement the plan on a small scale (pilot or trial).

-

Train employees and gather the necessary tools and resources.

-

Document the process and any issues encountered.

Example: The company rolls out the new system in one support team to test its effectiveness.

Check

Data will be used to analyze the plan results and check whether they meet the predetermined objectives.

-

Measure and evaluate the results of the implementation.

-

Compare actual results with expected outcomes.

-

Identify any deviations or unexpected outcomes.

Example: After a month, the company checks ticket resolution times and customer satisfaction scores.

Act

If the plan was successful, implement it on a wider scale and continuously assess your results. If the plan is not successful, begin the cycle again.

-

Standardize the successful parts of the plan.

-

Adjust the process to fix any problems.

-

Implement on a larger scale if successful.

-

Restart the PDCA cycle for further improvement.

Example: If results are positive, the company rolls out the system across all teams. If not, they revise the plan and go through the cycle again.

This methodology is widely used to improve efficiency and effectiveness in various fields, like business process management, project management, and software development.

Benefits of PDCA Cycle

-

Promotes continuous improvement.

-

Encourages data-driven decision making.

-

Helps reduce errors and inefficiencies.

-

Easy to understand and apply across industries.

Video Tutorial